In today’s warehouse and distribution environments, fire safety is not just a regulatory requirement—it is essential for protecting your people, your property, and your business continuity. Yet, even in well-managed facilities, fire and life safety plans often contain critical gaps that only become apparent during an emergency.

With over 40 years of experience supporting warehouses, logistics hubs, and industrial operations across North America, WPS Disaster Management Solutions has seen first-hand how a few common missteps can put workers at risk, disrupt operations, and expose organizations to legal and financial liabilities. Here are five of the most frequent warehouse fire safety planning mistakes—and how you can avoid them with a proactive, technology-driven approach.

1. Outdated Emergency Contacts and Response Roles

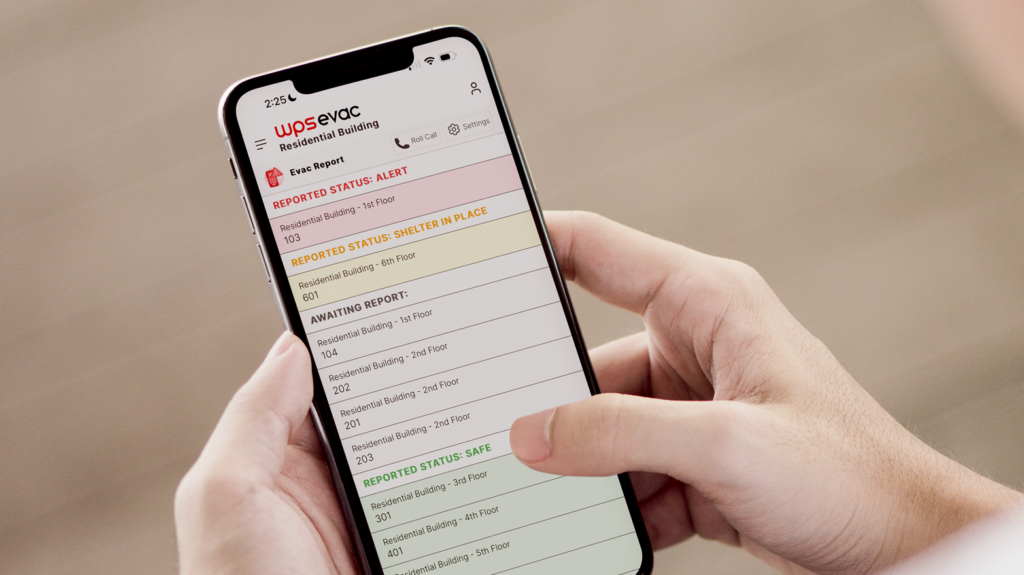

Warehouses often operate with rotating shifts and frequent changes in supervisory staff. Emergency contact lists and assigned roles can quickly become outdated, leading to confusion and delays during an incident. In an emergency, every second counts. The WPS Evac Management System centralizes and updates critical contacts and responsibilities in real time, ensuring that your team always has access to current information—no matter the shift or time of day.

2. Unclear Accountability During Emergencies

Even well-trained teams can falter if staff are not clear on their roles during an emergency. Who is responsible for directing teams to exits? Who checks high-risk areas like the shipping floor or mezzanine? Without clear accountability, response times suffer and safety is compromised. WPS enables you to assign, document, and communicate emergency roles so every team member knows exactly what to do when it matters most.

3. Relying on Generic Safety Plan Templates

Generic, one-size-fits-all fire safety plans do not reflect the unique risks and layouts of individual warehouses. Facilities storing flammable materials or operating high-density racking systems face very different hazards than those managing dry goods or minimal equipment. Effective fire safety planning requires a detailed understanding of your building’s structure, inventory, and operational flow. WPS empowers you to create customized, code-compliant plans tailored to the realities of your facility, not a generic checklist.

4. Inconsistent Fire Drills and Incomplete Documentation

Fire drills are often deprioritized in busy warehouse environments, and documentation is frequently missing or incomplete. This can leave your facility vulnerable during inspections or audits. WPS streamlines the scheduling, execution, and recording of fire drills, ensuring your training is consistent and your compliance records are always complete and accessible.

5. Failing To Update Plans as Facility Conditions Change

Warehouses are dynamic. As racking is reconfigured, new equipment is installed, or access points change, emergency routes and response plans must be updated. Treating safety plans as static documents creates a dangerous disconnect between your plan and the actual conditions on the ground. The WPS Evac Management System allows you to update your safety plans in real time, so your emergency procedures always reflect your current operations.

Safety, Compliance, and Operational Continuity: All in One Platform

Fire and life safety planning in warehouse environments is too important to leave to outdated processes or generic plans. By avoiding these five common mistakes, your facility will be better prepared for emergencies, more aligned with regulatory requirements, and more confident in its ability to protect people and assets.

WPS helps warehouse teams manage emergency procedures, train staff, maintain compliance, and respond with confidence—all from a centralized, user-friendly platform.

Request a Demo Today

Discover how WPS can support your facility’s fire and life safety strategy with customized, technology-driven solutions.